| Hummer Midgate Tailgate |

Buy It Now at ExtrudedSolutions.com

|

Buy It Now at

Amazon.com |

UTGS19L14in-Hum-1K |

|

ITEMS REQUIRED: Scissors, clean rag and soap solution.

Enclosed adhesion promoter will only be used for STEPS 2 and 4.Note: Standard, not Large, size Tailgate Seal was only used for this truck.

Included is a 14” length piece of Large Tailgate Seal; should the need arise.

See enclosed Common Cut Piece Positions insert card as a guideline.

Extreme temperatures will result in poor adhesive performance. Apply only if the air and surface temperature is between 55° - 105°F (13° - 40°C). Avoid touching adhesive after peeling off red liner. Repositioning of seal should not be done more than 2 times and only once if the temperature is above 80°F (27°C). |

STEP 1

Clean area thoroughly with soap and water solution and wipe completely dry. Use alcohol pads to prep the tape application areas and let dry. Images shown are for the left side of main tailgate and midgate. |

|

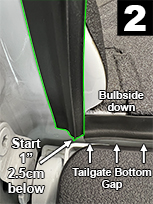

STEP 2: ATTACHING TO LEFT SIDEWALL OF MAIN TAILGATE

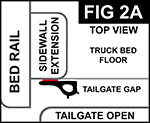

Put on protective glove and apply enclosed adhesion promoter to the side of plastic bedrail liner as shown in FIG 2A. Apply only to the area where the adhesive tape will secure. Allow 90 seconds to dry.

NOTE: The adhesion promoter will create an instant bond so do not attempt to remove or reposition.

Start 1” (2.5 cm) below truck bed floor and begin attaching seal to the sidewall extension (FIG 2, 2A, 2B & 2C). Continue straight up, applying light pressure to adhesive. When nearing top of sidewall, gradually rotate seal 90° counter clockwise so that bulb is facing forward and the taped side of seal is flush with the sidewall at the top (FIG 2B). Cut excess seal.

Close tailgate. If you see light through the sidewall, make adjustments by removing seal, except at the top where adhesion promoter was used, and repositioning. Apply very firm pressure (25lbs.) to secure adhesive.

Duplicate for right side. |

|

|

STEP 3: ATTACHING STANDARD SEAL TO TOP OF SIDEWALL

Cut a 3.25” (8.3cm) piece of Standard seal. Remove liner and attach as shown in (FIG 2B and 3). Close tailgate. If you see light through the sidewall, make adjustments by removing seal and repositioning. Apply very firm pressure (25lbs.) to secure adhesive.

Duplicate for right side. |

|

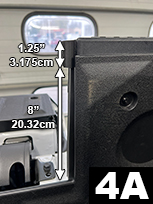

STEP 4: ATTACHING STANDARD SEAL TO LEFT SIDEWALL OF MIDGATE

Open Midgate. Cut a piece of Standard seal to 1.25” (3.2cm). Put on protective glove and apply enclosed adhesion promoter to side of the plastic tailgate liner where the adhesive will be adhered to �(FIG 4 and 4A). Allow 90 seconds to dry.

NOTE: The adhesion promote will create an instant bond so do not attempt to remove or reposition.

Peel off liner and attach as shown.

Apply very firm pressure (25lbs.) to secure adhesive bond.

Duplicate for right side. |

STEP 5: ATTACHING STANDARD SEAL TO LEFT SIDEWALL OF MIDGATE

Cut a piece of Standard seal to 8” (20.3cm). Peel off liner and begin attaching near the bottom of sidewall and with bulb side facing to the center. (FIG 4 and 4A). Continue up and flush to bottom of 1.25” (3.2cm) seal at the top. Close midgate. If you see light through sidewall, make adjustments by removing seal and repositioning. Do not attempt to remove or �reposition the 1.25” (3.2cm) seal (at top of midgate) where adhesion promoter was applied. Once seal is positioned apply very firm pressure (25lbs.) to secure adhesive bond.

Duplicate for right side |

STEP 6: ATTACHING TO BOTTOM PERIMETER OF MIDGATE USING STANDARD SEAL

Open midgate. Peel back a section of liner and begin attaching Standard seal, with bulb side facing outwards and flat edge of seal flush to the inside corner of midgate (FIG 6, 6A and 6B). Attach in sections and apply light pressure to adhesive. Gradually round corner (slight ripples will exist at the corners and will not affect performance) and attach for entire horizontal length (FIG 6B). Gradually round corner on the other side and cut to fit. Once seal is positioned apply very firm pressure (25lbs.) to secure adhesive bond. |

STEP 7: ATTACHING TO MAIN TAILGATE BOTTOM GAP USING STANDARD SEAL

Start at either end. Put on protective glove and apply enclosed adhesion to the polyurethane coated lip that drops down from the end of truck bed floor into the bottom gap (FIG 7). Allow 90 seconds to dry.

NOTE: The adhesion promote will create an instant bond so do not attempt to remove or reposition.

Pick up continuous roll of seal and peel off a portion of the liner and attach, bulb side down, as shown in (FIG 2 and 7A). Attach in 1” to 2” (2.5cm to 5cm) sections and apply light pressure to adhesive. Stop when 6" (15.3cm) from opposite end. Keeping adhesive off surface, cut seal where it will sit flush with the seal on the sidewall. Continue attaching. After seal is in place, apply very firm pressure (25lbs.) to secure the entire adhesive bond. |

|

|

STEP 8: LEAVE TAILGATE OPEN FOR 60 MINUTES

If the air temperature will fall below 50°F (10°C) within the next 24 hours or, if seals are attached to a surface other than paint, then leave tailgate(s) open for 24 hours.

|

|