| 2019 Ford Ranger |

CONTENTS: One roll of seal 9’ (2.74m) length. Two cut pieces of large seal measuring 0.88” (2.2cm) width by 4.50” (11.4cm) length. Two IPA pads.

ITEMS REQUIRED: Scissors, clean rag and soap solution. Extreme temperatures will result in poor adhesive performance. Apply only if air and surface temperature is between 55° - 105°F (13° - 40°C). If 45° - 55°F (7° - 13°C), you can use a hair dryer to warm the tape and surface of pickup.1’ (30cm) sections at a time, then apply seal. |

|

STEP 1:

Clean area thoroughly with soap and water solution and wipe completely dry. Use IPA pads to prep the tape application area and let dry. IMPORTANT: Wait until after each step is complete to apply very firm pressure to secure adhesive bond. If necessary, seal can be removed and repositioned up to 3 times, prior to applying very firm pressure. NOTE: Pictures shown are for application to left side only. Duplicate for right side after STEP 8.

STEP 2:

ATTACHING TO SIDEWALLS (Left Side) Lower tailgate

Cut a piece to 24” (61cm) from roll of seal. Remove adhesive liner completely and flush one end to tailgate hinge, aligning bulb so that fin of seal is slightly compressed to sidewall (FIG 1A). Apply light pressure to adhesive and continue upwards towards top of tailgate. Follow curve to the inside top of tailgate and stop (FIG 1B). Check alignment of seal by closing tailgate and simultaneously viewing seal compression from the rear of tailgate (FIG 1C). If seal is rolling too much, making it difficult to close tailgate, then reposition bulb in sections or entirely by lifting up on bulb to loosen adhesive and then repositioning. Open tailgate and cut away excess material so that top of seal aligns with the inside top of tailgate (FIG 1B). Once seal is positioned apply very firm pressure to secure the entire adhesive bond. |

|

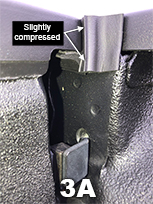

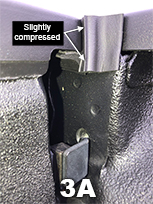

STEP 3: ATTACHING TO SIDEWALL TOP (Left Side)

Cut a 1.25” (3.2cm) piece from roll of seal. Close tailgate. Remover adhesive liner. You will be positioning top end of seal to top of sidewall (FIG 3A). Apply lightly to sidewall, bulb side facing out and slightly compress to both the inside top of tailgate and to seal on the inside top of tailgate (FIG 3A inside view) (FIG 3B outside view). Once seal is positioned apply very firm pressure to secure the entire adhesive bond.

|

|

STEP 4: ATTACHING PRE-CUT 4.50” (11.4cm) PIECE TO TAILGATE GAP (Left Side)

Remove adhesive liner and flush end of seal to sidewall while aligning the top of bulb with the lower ridge of truck bed floor (FIG 4A). Once seal is positioned apply very firm pressure to secure the entire adhesive bond. |

|

STEP 5: ATTACHING TO SIDEWALL BOTTOM (Left Side)

Open tailgate. Cut a 1.75” (4.5cm) piece from roll of seal. Remove adhesive liner. Lightly apply to sidewall, bulb side down slightly compressed to both the top of tailgate hinge and to seal on the tailgate gap (FIG 5A). Once seal is positioned apply very firm pressure to secure the entire adhesive bond. |

|

STEP 6: COVER BRACKET HOLE (Left Side)

Cut a 2” (5cm) piece from roll of seal. Remove adhesive liner. Use tips of finger to compress and push bulb into bracket hole (FIG 6A). Once seal is positioned apply very firm pressure to secure the entire adhesive bond.

STEP 7: ATTACHING PRE-CUT 4.50” (11.4cm) PIECE TO TAILGATE GAP (Right Side)

Remove adhesive liner and flush end to sidewall while aligning the top of bulb with the lower ridge of truck bed floor (Reference STEP 4 and FIG 4A for Left Side). Once seal is positioned apply very firm pressure to secure the entire adhesive bond.

|

|

STEP 8: ATTACHING TO TAILGATE GAP

You will be aligning the top of bulb with truck bed floor and flushing to 4.50” (11.4cm) length seal on the tailgate gap (FIG 8A). Take roll of seal, peel back liner and attach in sections, apply light pressure to adhesive. Flush with 4.50” (11.4cm) length seal on right side of tailgate gap and cut to fit. Close tailgate. If you see light coming through the tailgate gap, then remove and reposition entire seal up or down. Once seal is positioned apply very firm pressure to secure the entire adhesive bond. |

REPEAT STEPS 2, 3 5 AND 6 FOR RIGHT SIDE

FINAL STEP: After entire seal is in place, apply very firm pressure again to firmly secure the entire adhesive bond. If air temperature will fall below 55°F (13°C) within the next 24 hours or, if any part of seal is attached to a spray on bed liner, then leave tailgate open for 24 hours.

|