STEP 5:

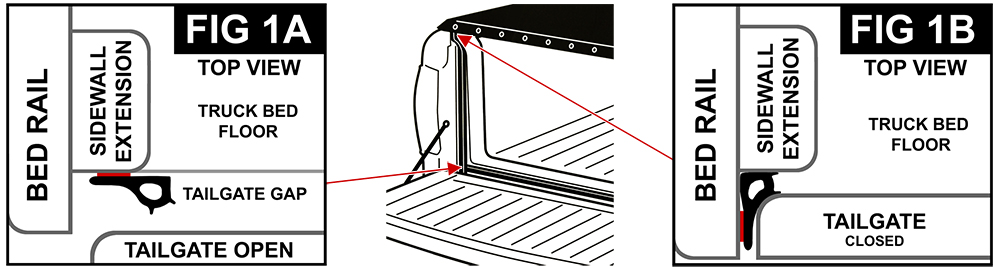

To evaluate the best positioning for the tailgate gap, cut a 1” (2.5cm) test piece and align the top of bulb with the truck bed floor. Stand to the side of truck and raise tailgate until bulb makes contact with tailgate.

NOTE: Compression and/or slight rolling of the bulb is okay, however, if the bulb rolls downwards too much as the tailgate is closing and you can see the tape, then seal has rolled too much. This can cause added stress on the adhesive and possible separation.

If you see that the bulb is rolling too much then invert 1” test piece so that bulb side is down. Raise tailgate and make sure no light is visible through the 1” piece. Adjust 1” piece higher or lower to seal out the light. After determining if the bulb should be up or down and how high or low, remove 1” piece and pick up one end of the continuous seal. For 2021 and newer, position bulb side down for the last 12.25”(31.12cm) of the right side of tailgate gap (5A).

Start at either end, peel back a section of liner and flush to seal on the sidewall. Attach in sections and apply light pressure to adhesive. Flush to seal on the other sidewall and cut to fit. Apply very firm pressure to secure adhesive bond. |