New & Improved: Uses 2 less cut pieces

Ford F150, F250, F350, F450, Raptor and Lightning |

Kit contains Standard and Large Tailgate Seal with Taper Seal®

Clean area thoroughly with soap and water solution and wipe completely dry. Use alcohol pads to prep the tape application area and let dry. Wait until after Tailgate Seal is installed before applying very firm pressure, to secure adhesive bond. Adhesive requires 25lbs of pressure to bond. If necessary, Tailgate Seal can be removed and repositioned prior to applying very firm pressure. Pictures shown are for the left sidewall and tailgate gap. |

|

STEP 1: ATTACHING TO SIDEWALL USING LARGE TAILGATE SEAL

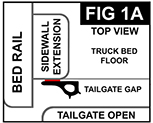

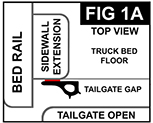

Start 1” (2.5cm) below truck bed floor and attach Large Tailgate Seal to the rear corner edge of the left sidewall extension (FIG 1A). Start from bottom and stop when centered with the rubber stop. Cut at a 45° angle (FIG 1B). Apply light pressure to adhesive. Duplicate for right sidewall. |

|

|

STEP 2: ATTACHING TO TOP OF SIDEWALL USING STANDARD TAILGATE SEAL

Cut a 2.5" (6.35cm) piece of Standard Tailgate Seal. Attach so that bulb is facing inward and the taped side of seal is flush with the sidewall (FIG 2). If adhesive is being applied to a surface other than paint, then use enclosed Adhesion Promoter after determining position and prior to attaching seal. Apply firm pressure to adhesive. Duplicate for right sidewall. |

|

STEP 3: ATTACHING TO SIDE OF TAILGATE USING STANDARD TAILGATE SEAL

Cut a 2.25" (5.7cm) piece of Standard Tailgate Seal. Attach to the side of tailgate near the top, bulb side facing upwards (FIG 3A and 3B). Apply light pressure. Check that bottom of seal does not interfere with rubber stop by lifting tailgate, but not closing and inspecting from the outside rear. Adjust seal as necessary. NOTE: For larger gaps substitute Standard seal with Large seal. Duplicate for right side. |

|

STEP 4

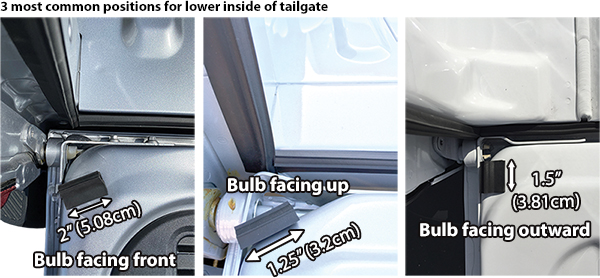

Close tailgate. If you see light through the sidewalls make adjustments by removing the seal(s) and repositioning. If there is still light then cut pieces of seal, as needed and attach to sidewalls and/or tailgate (refer to enclosed insert card showing common cut piece positions). NOTE: Some trucks will need an extra cut piece on lower inside of tailgate (see image below). Open tailgate. Apply very firm pressure to secure adhesive bond. |

|

|

|

STEP 5: ATTACHING TO TAILGATE GAP USING STANDARD TAILGATE SEAL

Most often bulb side is up for all Ford trucks (FIG 5A). For 2021 and newer models, with a Hinge Retainer Bracket, bulb will be positioned down for the last 15 ½” (39.37cm) on the right side of tailgate gap (FIG 5B and 5C).

To evaluate the best positioning for the tailgate gap, cut a 1” (2.5cm) test piece and align the top of bulb with the truck bed floor. Stand to the side of truck and raise tailgate until bulb makes contact with tailgate. (One minute video available at TailgateSeal.com).

Compression and/or slight rolling of the bulb is okay, however, if the bulb rolls downwards too much as the tailgate is closing and you can see the tape, then seal has rolled too much. This can cause added stress on the adhesive and possible separation. If you see that the bulb is rolling too much then invert 1” test piece so that bulb side is down. Raise tailgate and make sure no light is visible through the 1” piece. Adjust 1” piece higher or lower to seal out the light. After determining if the bulb should be up or down and how high or low, remove 1” piece and pick up one end of the continuous seal.

Start at either end, peel back a section of liner and flush end of seal to seal on the sidewall (FIG 5A). Attach in sections and apply light pressure to adhesive. Flush to seal on the other sidewall and cut to fit. Apply very firm pressure (25lbs) to secure adhesive bond. |

|

STEP 6:

After Tailgate Seal is in place, apply very firm pressure to secure the entire adhesive bond. Leave tailgate open for 30 minutes. If the air temperature will fall below 50°F (10°C) within the next 24 hours or, if applied to a surface other than paint, such as plastic or a spray on bed liner, then leave tailgate open for 24 hours. |

| |

|

|

| Inside views of tailgate when closed |